The Soyuz launch vehicle family has provided reliable and efficient launch services since the start of space exploration. Soyuz rockets, which launched both the first artificial satellite and the first man into space, have been credited with more than 1,825 launches to date. Today, Soyuz is used for manned and unmanned flights to the International Space Station, as well as Russian government launches, and commercial launches with Arianespace as launch operator.

The decision of the European Space Agency to introduce Soyuz launch capability at the Guiana Space Center (CSG) marked a major step forward in expanding the range of missions. With the introduction of Soyuz at CSG, this famed Russian launch vehicle is now an integral part of the European launcher fleet,together with the heavy-lift Ariane 5 and the light Vega. Offered exclusively by Arianespace to the commercial market, for launches from CSG, Soyuz becomes Europe’s standard medium launcher for both government and commercial missions.

On October 21, 2011 Arianespace successfully launched the first Soyuz rocket from the Guiana Space Center (CSG) in French Guiana, orbiting the first two satellites in the GALILEO constellation. The Samara Space Center in Russia continues to produce Soyuz launchers. Because of sustained demand from the Russian government, International Space Station requirements and Arianespace’s commercial orders, the Soyuz is being produced at an average rate of 15 to 20 launchers per year.

The manufacturer can also rapidly scale up to accommodate market demand. In fact, annual Soyuz production peaked in the early 1980’s at 60 vehicles per year.

Soyuz is a reliable, efficient,and cost-effective solution for a full range of missions, from LEO to Mars or Venus. Offering an unrivaled heritage, Soyuz has already performed almost every type of mission, from telecommunications, Earth observation, weather and scientific satellites, to manned spacecraft. It is a very scalable and flexible launch vehicle.

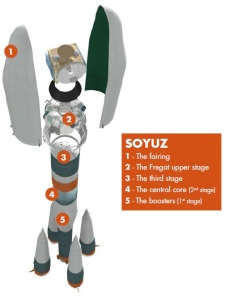

The Soyuz version currently offered by Arianespace is a four-stage launch vehicle: four boosters (first stage), a central core (second stage), a third stage, and the restartable Fregat upper stage (fourth stage). It also includes a payload adapter/dispenser and fairing.

Boosters (first stage)

The four cylindrical-conical boosters are assembled around the central core. The booster’s RD-107A engines are powered by liquid oxygen and kerosene, the same propellants used on each of the lower three stages. The kerosene tanks are located in the cylindrical part and the liquid oxygen tanks in the conical section. Each engine has four combustion chambers and four nozzles. Three-axis flight control is provided by aerofins (one per booster) and steerable vernier thrusters (two per booster). Following liftoff, the boosters burn for approximately 118 seconds and are then jettisoned. Thrust is transferred to the vehicle through a ball joint located at the top of the conical structure of the booster, which is attached to the central core by two rear struts.

Central core (second stage)

The central core is similar in construction to the four boosters, with a special shape to accommodate the boosters. A stiffening ring is located at the interface between the boosters and the core. This stage is fitted with an RD-108A engine, also comprising four combustion chambers and four nozzles. It also has four vernier thrusters, used for three-axis flight control once the boosters have separated. The core stage has a nominal burn time of 286 seconds. The core and boosters are ignited simultaneously on the launch pad, 20 seconds before liftoff. Thrust is first adjusted to an intermediate level to check engine readings. The engines are then gradually throttled up, until the launcher develops sufficient thrust for liftoff.

Third stage

The third stage is linked to the central core by a latticework structure. Ignition of the third stage’s engine occurs approximately two seconds before shutdown of the central core engine. The third stage engine’s thrust enables the stage to separate directly from the central core. Between the oxidizer and fuel tanks is a dry section where the launcher’s avionics systems are located. The third stage uses either a RD-0110 engine in a ST-A version, or a RD-0124 engine in a ST-B version.

Fregat upper stage (fourth stage)

Flight qualified in 2000, the Fregat upper stage is an autonomous and flexible stage that is designed to operate as an orbital vehicle. It extends the capability of the Soyuz launcher, now covering a full range of orbits (LEO, SSO, MEO, GTO, GEO and escape). To ensure high reliability for the Fregat stage right from the outset, various flight-proven subsystems and components from previous spacecraft and rockets are used. The upper stage consists of six spherical tanks (four for propellants, two for avionics) arranged in a circle and welded together. A set of eight struts through the tanks provide an attachment point for the payload, and also transfer thrust loads to the launcher. The upper stage is independent from the lower three stages, since Fregat has its own guidance, navigation, attitude control, tracking, and telemetry systems. The stage’s engine uses storable propellants – UDMH (unsymmetrical dimethyl hydrazine) and NTO (nitrogen tetroxide) – and can be restarted up to 20 times in flight, thus enabling it to carry out complex missions. It can provide the customer with 3-axis or spin stabilization of their spacecraft.

The Fregat upper stage is encapsulated in a fairing with the payload and a payload adapter/dispenser

The fairing

Soyuz launchers operated by Arianespace at CSG use the ST fairing in standard configuration, with an external diameter of 4.1 meters and a length of 11.4 meters.

Roscosmos, the Russian space agency, is responsible for license allocations and intergovernmental relations. it is the launch authority in charge of range operations. RKTs-Progress (Samara Space Center) is responsible for the design, development, and manufacture of launch vehicles, including the Soyuz launch vehicle’s first, second and third stages and fairing. It also integrates vehicle stages and handles flight operations. NPO Lavochkin manufactures and integrates the Fregat upper stage, and is responsible for launch operations. TsENKI is in charge of launch planning and the provision of associated services, including systems engineering, and the design, and technical and operational management of the launch pad and associated facilities dedicated to the Soyuz launcher.

The countdown comprises all final preparation steps for the launcher, the satellite and the launch site. If it proceeds as planned, the countdown leads to the ignition of the core stage engine and the four boosters.

For 40 years, the Guiana Space Center (CSG), Europe’s Spaceport in French Guiana, has offered a complete array of facilities for rocket launches. It mainly comprises the following:

- CNES/CSG technical center, including various resources and facilities that are critical to launch base operations, such as radars, telecom network, weather station, receiving sites for launcher telemetry, etc.

- Payload processing facilities (ECPU), in particular the S5 facility.

- Ariane, Soyuz and Vega launch complexes, comprising the launch zones and launcher integration buildings.

- Various industrial facilities, including those operated by Regulus, Europropulsion, Air Liquide Spatial Guyane and Airbus Defence and Space, all involved in the production of Ariane 5 components. A total of 40 European manufacturers and local companies are involved in operations.

Europe’s commitment to independent access to space is based on actions by three key players: the European Space Agency (ESA), French space agency CNES and Arianespace. ESA is responsible for the Ariane, Soyuz and Vega development programs. Once these launch systems are qualified, ESA transfers responsibility to the operator Arianespace. ESA has helped change the role of the Guiana Space Center, in particular by funding the construction of the launch complexes, payload processing buildings and associated facilities. Initially used for the French space program, the Guiana Space Center has gradually become Europe’s own spaceport, according to the terms of an agreement between ESA and the French government. To ensure that the Spaceport is available for its programs, ESA takes charge of the lion’s share of CNES/CSG fixed expenses, and also helps finance the fixed costs for the ELA launch complexes.

French space agency CNES has several main responsibilities at the Guiana Space Center : It designs all infrastructures and, on behalf of the French government, is responsible for safety and security. It provides the resources needed to prepare the satellites and launcher for missions. Whether during tests or actual launches, CNES is also responsible for overall coordination of operations, collects and processes all data transmitted from the launcher via a network of receiving stations, to track Ariane, Soyuz and Vega rockets throughout their trajectories.